About Fusion Europe

Explore the cutting-edge advancements in brazing technology with Fusion Europe, the premier leaders in serving diverse industrial sectors worldwide, including HVAC, electrical, tooling, automotive, jewellery, aerospace and beyond. Fusion’s extensive knowledge base, has allowed us to provide tailored brazing paste solutions for an array of applications, including:

- Diamond and carbide tooling

- Industrial and domestic refrigeration systems

- Electrical connectivity components

- Fire suppression systems

- Various heating, cooling, and sanitation apparatuses

- Aerospace and aviation components

- Fine silverware and jewellery crafting

- Radiator assemblies

- Automotive emission control systems

- Heating elements for household appliances

- Plumbing and hydraulic systems

- Musical instrument manufacturing

- Solar energy infrastructure

With a rich heritage spanning nine decades of pioneering metal-joining techniques, our consultancy services and expert brazing team establish the benchmark for excellence. Operating from strategic locations in the UK and US, our solutions reach across Europe and worldwide, ensuring unparalleled expertise and support.

Our Products

Explore our extensive range of brazing and soldering pastes, powders, fluxes, applicators, and automation solutions. At Fusion Europe, we specialise in delivering high-quality products tailored to meet your brazing and soldering needs.

Brazing Pastes

Soldering Pastes

Fluxes

Applicators & Automation

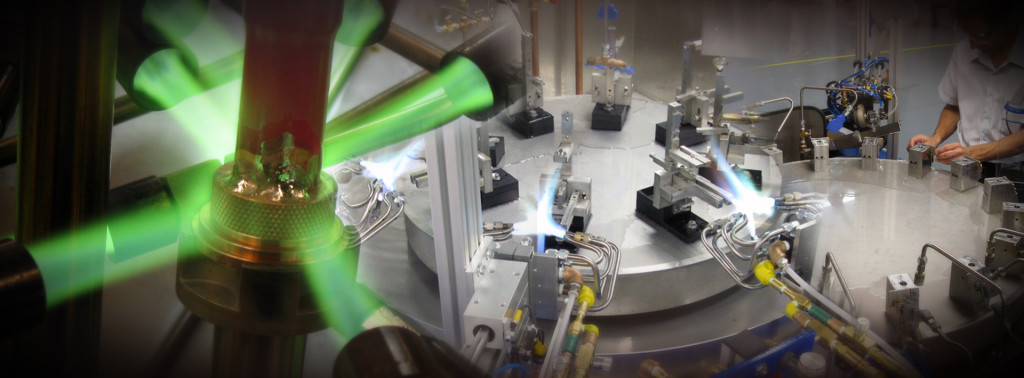

What We Do

Fusion Europe stands at the forefront as the premier manufacturer of brazing and soldering pastes and powders. Our expertise extends to filler metals, flux, binders, and comprehensive consultancy services. Explore our top-quality products and tailored consultancy solutions for your brazing and soldering needs.

Filler Metals

Filler Metals profoundly influence joint strength, chemical compatibility, and properties like corrosion resistance. The interaction between base metal and filler metal depends on heating cycle and filler melting temperature.

Flux and Binders

Fluxes remove and prevent oxides on base and filler metals during heating. Binders ensure a homogenous mix of flux and filler metal, limiting their interaction.

Consultancy

We deliver innovative metalworking solutions for robust manufacturing processes. Our expertise recommends the ideal brazing product for any challenge, integrating it seamlessly into your operation, whether manual or automated.

Request A Free Paste Sample

To receive a Free sample of brazing or soldering paste, please fill out the following information: