FREQUENTLY ASKED QUESTIONS (FAQ)

Explore our comprehensive list of frequently asked questions (FAQ) to find answers to common inquiries about brazing with paste.

If you are not able to find the answers to your enquiry here, please contact our Technical Team on infoeurope@fusion-inc.com for more assistance.

1. What is brazing paste and how does it work?

Brazing paste is a mixture of brazing filler metal powder, flux and binder which is custom blended to meet the application requirements. It is an advanced form of brazing material that can be easily applied to joint metallic parts using various heating methods. When applied to the joint surfaces of metal parts, the paste adheres to the surfaces, ensuring proper contact and distribution of the brazing material. During heating, the binder in the paste evaporates, leaving behind a layer of brazing filler metal and flux on the joint surfaces. The flux serves multiple purposes: it removes oxides and contaminants from the surfaces, promotes wetting of the filler metal, and helps to facilitate the flow of the molten filler metal into the joint. As the temperature continues to rise, the brazing filler metal melts and flows into the joint by capillary action, creating a metallurgical bond between the parts. Once the joint cools and solidifies, the brazing paste residue can be cleaned off, leaving behind a strong and durable brazed joint.

2. What is Capillary Attraction in brazing?

Capillary attraction in brazing refers to the phenomenon where molten filler metal is drawn into the narrow gap or space between closely fitting joint surfaces due to surface tension forces. This occurs when the molten filler metal encounters a clean, properly prepared joint with closely matched surfaces. During the brazing process, as the temperature of the assembly increases and the filler metal reaches its melting point, it becomes fluid and flows along the joint surfaces by capillary action. The surface tension of the molten filler metal causes it to be pulled or drawn into the narrow gap between the joint surfaces, filling the entire joint through capillary action.

Capillary attraction is critical in brazing as it ensures that the molten filler metal uniformly wets and bonds with the joint surfaces, creating a strong and durable brazed joint. It also helps to distribute the filler metal evenly throughout the joint, minimizing the formation of voids or defects and ensuring proper metallurgical bonding between the joined components. Proper joint design, surface preparation, and brazing technique are essential to optimize capillary attraction and achieve high-quality brazed joints.

3. How do I properly apply brazing paste?

Properly applying brazing paste involves several key steps:

1. Clean Surfaces: Ensure that the surfaces to be brazed are clean and free from contaminants, such as oil, grease, or oxides, which can affect the quality of the brazed joint.

2. Mixing: If the brazing paste requires mixing, thoroughly mix the paste according to the manufacturer’s instructions to ensure uniformity and proper performance.

3. Application: Use a suitable applicator, such as a brush, syringe, or dispenser, to apply the brazing paste evenly to the joint surfaces. Apply enough paste to cover the entire joint area, but avoid excessive build-up.

4. Joint Assembly: Assemble the parts to be brazed together, ensuring proper alignment and fit-up. Apply slight pressure to ensure good contact between the joint surfaces and the brazing paste.

5. Heating: Heat the assembly uniformly and gradually to the recommended brazing temperature using an appropriate heating method, such as torch, induction, or furnace brazing, depending on the application and materials involved.

6. Brazing: As the assembly reaches the brazing temperature, the brazing paste will begin to liquefy, flow, and bond the joint surfaces together. Maintain the temperature for the specified brazing time to ensure complete bonding.

7. Cooling and Cleaning: Allow the brazed assembly to cool naturally or quench it as required. Once cooled, clean off any remaining brazing paste residue using a suitable cleaning method, such as brushing, wiping, or chemical cleaning.

By following these steps and adhering to Fusion recommendations, you can ensure proper application of brazing paste and achieve high-quality brazed joints.

4. Why is brazing paste better than traditional forms for brazing?

Brazing paste offers several advantages over traditional forms of brazing. Its paste-like consistency allows for precise application, even in intricate or hard-to-reach areas, resulting in reduced material waste and improved joint quality. Additionally, the flux contained within the paste helps to clean and prepare the joint surfaces, promoting better wetting and adhesion of the filler metal. Brazing paste typically requires lower heating temperatures and shorter cycle times, leading to energy savings and increased efficiency in the brazing process. Overall, brazing paste provides a more versatile, cost-effective, and user-friendly solution for joining metal components compared to traditional brazing methods.

5. What are the advantages of induction brazing compared to flame brazing?

Induction brazing offers several advantages over flame brazing. Firstly, induction brazing provides precise, localized heating, which allows for better control over the brazing process and minimizes the risk of overheating or damaging the surrounding materials. Secondly, induction brazing is typically faster than flame brazing, resulting in higher production rates and increased efficiency. Additionally, induction brazing eliminates the need for an open flame, reducing the risk of fire hazards and creating a safer working environment. Furthermore, induction brazing can be automated more easily, leading to consistent results and reduced labour costs.

6. Why should we choose Fusion Incorporated UK Ltd?

Fusion Incorporated UK Ltd. specializes in providing tailored solutions for brazing applications, offering expertise in induction, flame, furnace brazing and other heating methods. Our company is committed to delivering high-quality products and services, ensuring that your brazing processes meet tight production tolerances and deliver consistent results.

Fusion Incorporated UK Ltd. offers personalized customer support, with a dedicated Technical/Sales Team available to assist you with any brazing inquiries or challenges. Additionally, our company prioritizes innovation and efficiency, continuously working towards improvement in cost structures and lean manufacturing processes. Working with Fusion Incorporated UK Ltd. means partnering with a trusted industry leader dedicated to delivering reliable, high-performance solutions for your brazing applications.

7. What are the advantages of using silver brazing paste in the manufacture of carbide tools?

Silver brazing paste provides excellent wetting and flow characteristics, ensuring strong and uniform joints between carbide inserts and tool bodies. Fusion pastes use a fluxed binder which helps to remove oxides and contaminations from the joint surface. When using silver brazing paste in carbide tool manufacturing, it contributes to high quality and increased productivity.

8. Are there different types of pastes available, and how do I choose the right one for my application?

Yes, there are different types of brazing pastes available, each designed for specific applications and materials. Some common types of brazing pastes include:

1. Silver Brazing Paste: Contains silver-based filler metals and flux, suitable for joining a wide range of metals, including steel, stainless steel, copper, and brass. Silver brazing paste offers high strength and thermal conductivity, making it suitable for applications requiring excellent mechanical properties.

2. Copper/CuP Brazing Paste: Contains copper-based filler metals and flux, ideal for joining copper and copper alloys. Copper brazing paste provides good electrical conductivity and corrosion resistance, making it suitable for electrical and plumbing applications.

3. Aluminium Brazing Paste: Contains aluminum-based filler metals and flux, specifically designed for joining aluminum and aluminum alloys. Aluminum brazing paste offers excellent corrosion resistance and is commonly used in automotive and HVAC applications.

4. Nickel Brazing Paste: Contains nickel-based filler metals and flux, suitable for joining nickel alloys, stainless steel, and other high-temperature materials. Nickel brazing paste offers high strength and oxidation resistance, making it suitable for applications requiring elevated temperature performance.

When choosing the right brazing paste for your application, consider the following factors:

- Base Materials: Select a brazing paste that is compatible with the materials you are joining. Ensure that the filler metal in the paste is suitable for the base metals’ composition and metallurgical properties.

- Operating Conditions: Consider the operating conditions of your application, such as temperature, pressure, and environment. Choose a brazing paste that can withstand these conditions and provide the required mechanical and corrosion resistance properties.

- Joint Design: Evaluate the joint design and geometry to determine the best brazing paste formulation and application method. Some pastes may be more suitable for specific joint configurations or gap sizes.

- Manufacturer Recommendations: Fusion can provide full guidance on selecting the right paste formulation, application method, and brazing parameters to achieve optimal results.

To explore the complete Fusion product portfolio, please contact our Sales Team on infoeurope@fusion-inc.com.

9. What are the typical brazing temperatures and heating methods when using paste?

The typical brazing temperatures and heating methods when using brazing paste can vary depending on the specific materials being joined and the requirements of the application. However, some general guidelines apply:

1. Brazing Temperatures: Brazing temperatures typically range from 450°C to 1200°C, depending on the melting points of the filler metal and the base materials. It’s essential to select a brazing temperature that is above the melting point of the filler metal but below the melting points of the base metals.

2. Heating Methods: Several heating methods can be used when brazing with paste, including:

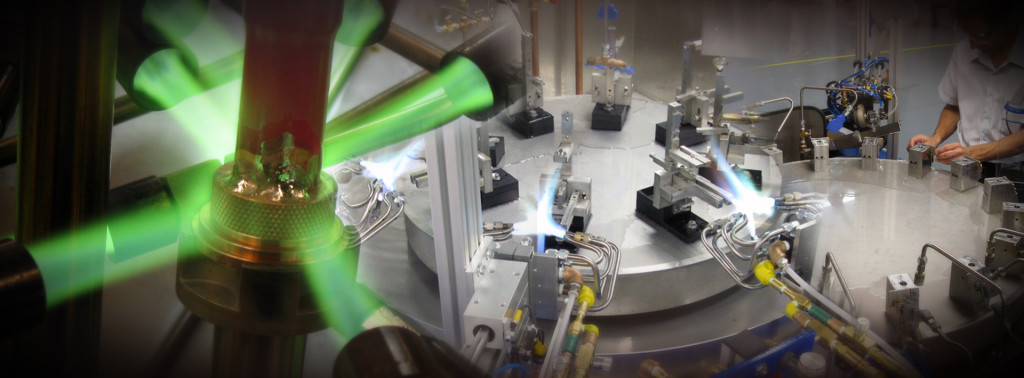

- Torch Brazing: This method involves using a flame torch to heat the brazing assembly to the required temperature. Torch brazing is suitable for smaller parts and assemblies that require localized heating.

- Furnace Brazing: Furnace brazing involves placing the brazing assembly inside a furnace and heating it to the desired temperature. Furnace brazing is ideal for larger or more complex assemblies and allows for precise temperature control and uniform heating.

- Induction Brazing: Induction brazing uses electromagnetic induction to heat the brazing assembly quickly and efficiently. This method is suitable for both small and large parts and offers precise control over heating patterns and cycle times.

- Resistance Brazing: Resistance brazing uses electrical resistance to generate heat within the brazing assembly. This method is often used for joining smaller parts or components with complex geometries.

It’s essential to select the most appropriate heating method based on factors such as the size and shape of the parts, the desired heating rate, and the required temperature uniformity. Additionally, proper control of heating parameters, such as temperature, heating rate, and cycle time, is crucial to ensure the quality and integrity of the brazed joints.

10. Can brazing paste be used for various metals and alloys?

Yes, brazing paste can be used for various metals and alloys, making it a versatile option for joining different materials in a wide range of applications. Brazing paste formulations are available to suit specific combinations of base metals and filler metals, providing compatibility with materials such as:

- Steel

- Stainless steel

- Copper

- Brass

- Aluminum

- Bronze

- Nickel alloys

- Titanium

- Carbide

The filler metals in brazing paste formulations are typically selected based on their melting points, wettability, and compatibility with the base metals being joined. By selecting the appropriate brazing paste formulation for the specific materials and application requirements, manufacturers can achieve strong, reliable, and high-quality brazed joints across a variety of metal combinations.