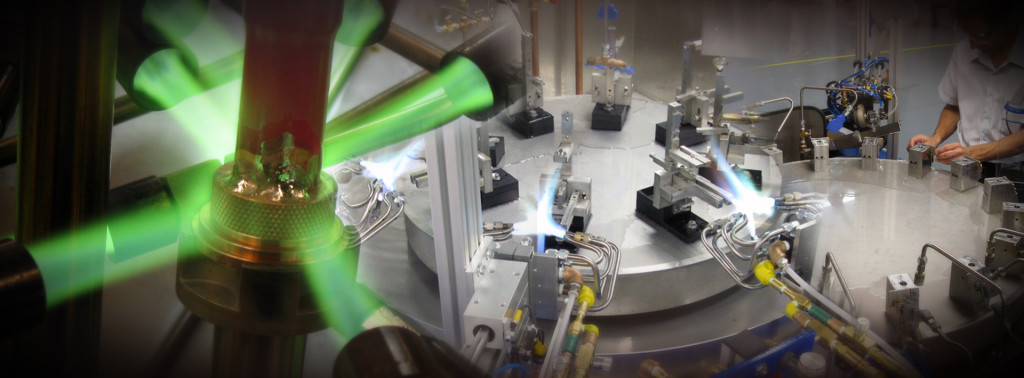

Filler Metals

Filler metals play a crucial role in ensuring both the structural integrity of joints and chemical compatibility.

The level of metallurgical interaction between the base metal and filler metal depends on the specific application. The extent of this interaction at grain boundaries is primarily influenced by the time and temperature at which the filler metal reaches its liquidus state. The two key factors determining base metal/filler metal interaction are therefore the heating cycle time and the melting temperatures of the filler metal.

A faster heating cycle and lower melting temperature of the filler metal generally result in a milder interaction. On the other hand, longer durations at higher temperatures tend to intensify this interaction. The degree of metallurgical interaction significantly impacts the mechanical and physical properties of both the base metals and the filler metal. It also plays a role in attributes such as corrosion resistance and strength. Consequently, selecting the appropriate filler metal for the application and optimising the brazing process are critical steps.

By carefully considering these factors and making informed choices, you can ensure the optimal performance and longevity of joints. Our comprehensive range of filler metals and brazing paste solutions is designed to meet your specific needs.

Details of the appropriate filler metals for compatibility with base metals can be found in our brochure. For more details and to discover how our expertise can enhance your brazing process and achieve exceptional results, please get in touch with our Technical Services team.